1. Copper-nickel, chromium platings and multi-layer nickel, chromium platings on steel parts base.

2. Does not corrode the substrate, and the substrate can maintain its original metallic luster after removal.

3. The metal that has been removed is not easy to produce a suspension layer, and the life of the strip plating liquid is long.

4. Fast etching speed.

Ingredients | Scope | Unit |

FH70 remover | 200-250 | g/L |

pH value | 4-6 | ml/L |

Temperature | 15-45 | °C |

Current density | 5-10 | A/dm2 |

Cathode | Iron plate or stainless steel |

With advanced formulation technology, FH-70 provides fast stripping speed, stable performance, excellent compatibility, and low environmental impact, making it a reliable choice for both large-scale industrial production and precision component processing.

Electroplating stripping agents play a vital role in surface finishing and plating repair processes. The FH-70 Copper, Nickel, Chromium Stripping Agent is specifically formulated to remove multi-layer metal coatings such as copper, nickel, and chromium without damaging the base material.

Developed with cutting-edge R&D technology and supported by ISO9001:2004 quality management standards, FH-70 ensures consistent stripping efficiency while maintaining safe operational conditions. This product integrates advanced additives imported from international electroplating industries, ensuring high-quality performance that meets the demands of modern manufacturing.

FH-70 is suitable for a wide range of stripping baths and can be applied in both manual and automatic electroplating production lines. It is compatible with ferrous and non-ferrous substrates, making it a versatile solution for different industries requiring metal coating removal and reprocessing.

Multi-metal stripping capability – Efficiently removes copper, nickel, and chromium coatings.

High stripping speed – Ensures rapid removal, improving production efficiency.

Excellent substrate protection – Does not corrode or damage base materials during stripping.

Stable chemical performance – Maintains stripping efficiency even after long-term use.

Environmentally responsible formulation – Designed with reduced toxicity for safer handling and lower environmental impact.

Wide application compatibility – Suitable for different plating lines including rack plating, barrel plating, and precision plating processes.

Cost-effective – Long bath life and consistent performance reduce chemical consumption.

Copper Stripping: Removes copper layers from electronic parts, connectors, and decorative plating.

Nickel Stripping: Effective for eliminating nickel underlayers in multi-coating systems.

Chromium Stripping: Safely strips decorative and functional chromium coatings from components.

Rework & Recycling: Enables recovery and reuse of base materials by removing defective coatings.

Surface Preparation: Ensures a clean substrate for re-plating and surface refinishing.

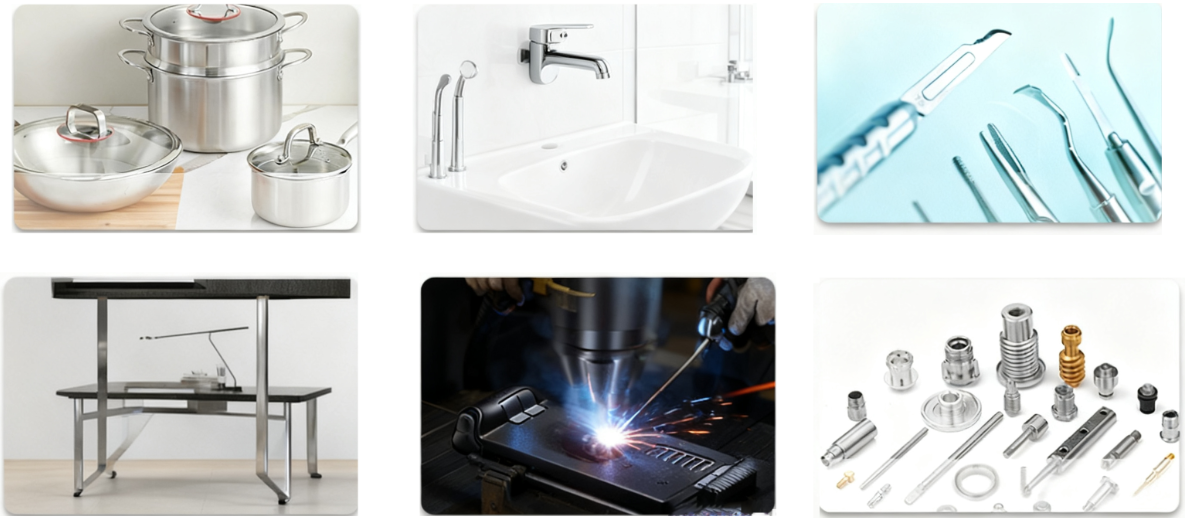

The FH-70 Copper, Nickel, Chromium Stripping Agent is widely applied in:

Electronics Industry: Stripping coatings from PCB components, connectors, and precision micro-parts.

Automotive Industry: Used for reworking decorative chrome and nickel-plated automotive components.

Hardware Manufacturing: Stripping defective plating from tools, fasteners, and decorative hardware.

Aerospace & Aviation: Applied for maintenance and re-plating of high-precision aircraft parts.

Medical Equipment: Ensures high-purity stripping for stainless steel surgical instruments and devices.

General Metal Finishing: Suitable for industries requiring surface restoration and re-plating.

Q1: What metals can FH-70 strip?

A1: FH-70 is formulated to strip copper, nickel, and chromium coatings effectively without damaging the base substrate.

Q2: Is FH-70 safe to use on all base materials?

A2: Yes, FH-70 is designed to protect ferrous and non-ferrous base metals during the stripping process, ensuring no corrosion or pitting occurs.

Q3: How fast is the stripping process with FH-70?

A3: The stripping speed depends on coating thickness and bath conditions, but FH-70 offers rapid removal compared to conventional stripping Solutions.

Q4: Can FH-70 be used in automatic plating lines?

A4: Yes, FH-70 is fully compatible with both manual and automated stripping systems, making it ideal for large-scale industrial applications.

Q5: What are the safety precautions when using FH-70?

A5: Operators should use appropriate protective equipment (gloves, goggles) and ensure adequate ventilation. The formulation is Environmentally Friendly but should still be handled according to standard chemical safety practices.

Q6: Does FH-70 require frequent bath replacement?

A6: No, FH-70 has a long bath life and maintains consistent performance, reducing the frequency of solution replacement.

Q7: How does FH-70 compare to traditional stripping agents?

A7: FH-70 offers faster stripping speed, better substrate protection, and lower environmental impact compared to traditional high-toxicity solutions.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.