Nickel barrel plating is widely used in modern manufacturing, especially for small components such as screws, fasteners, connectors, and precision hardware. Compared to rack plating, barrel plating requires additives that can deliver uniform bright deposits while minimizing burning, pitting, and uneven thickness.

The FH-808 Nickel Barrel Plating Brightener is engineered with advanced additives imported from international electroplating technology. Its formulation provides high throwing power, consistent brightness across large loads, and strong wear- and corrosion-resistance of the deposit.

By combining advanced chemical stability with cost-effective performance, FH-808 meets the needs of continuous production lines and mass finishing operations while complying with international plating standards.

Brilliant Brightness – Produces highly reflective and bright nickel coatings.

Excellent Leveling Ability – Smooths surface imperfections and provides uniform coverage.

High Throwing Power – Ensures even plating on both inner and outer surfaces of small components.

Strong Adhesion – Prevents peeling and ensures a long-lasting nickel deposit.

Stable Bath Performance – Maintains effectiveness in large-scale continuous barrel operations.

Versatility – Suitable for a wide range of ferrous and non-ferrous substrates.

Cost-Effective – Reduces additive consumption and prolongs bath life.

Bright Nickel Coating – Provides a smooth, mirror-like nickel finish.

Corrosion Protection – Enhances resistance to oxidation and wear.

Decorative Effect – Improves appearance of hardware and consumer products.

Base Layer for Further Plating – Serves as an undercoat for chrome, gold, or other final plating layers.

Functional Surface Improvement – Strengthens hardness and durability of plated components.

Ingredients | Scope | Unit |

Nickel sulfate | 200-250 | g/L |

Nickel chloride | 50-60 | g/L |

Borax | 40-50 | g/L |

FH808 Brightener | 0.1-0.4 | ml/L |

FH808 Positioning Agent | 4-8 | ml/L |

Temperature | 50-60 | °C |

pH value | 4.0-4.5 | |

Voltage | 12-15 | V |

Reliable Mass Production – Specially designed for barrel plating in large-scale industrial applications.

Uniform Results – Achieves consistent brightness across complex geometries and bulk loads.

Ease of Operation – Simplified bath maintenance and easy monitoring reduce downtime.

Enhanced Efficiency – Faster plating rates save time and increase productivity.

Proven Quality – Developed under strict ISO9001:2004 quality management standards.

Wide Industry Applications – Suitable for electronics, automotive, aerospace, fasteners, and consumer hardware.

Eco-Optimized Formulation – Lower toxicity compared with conventional additives.

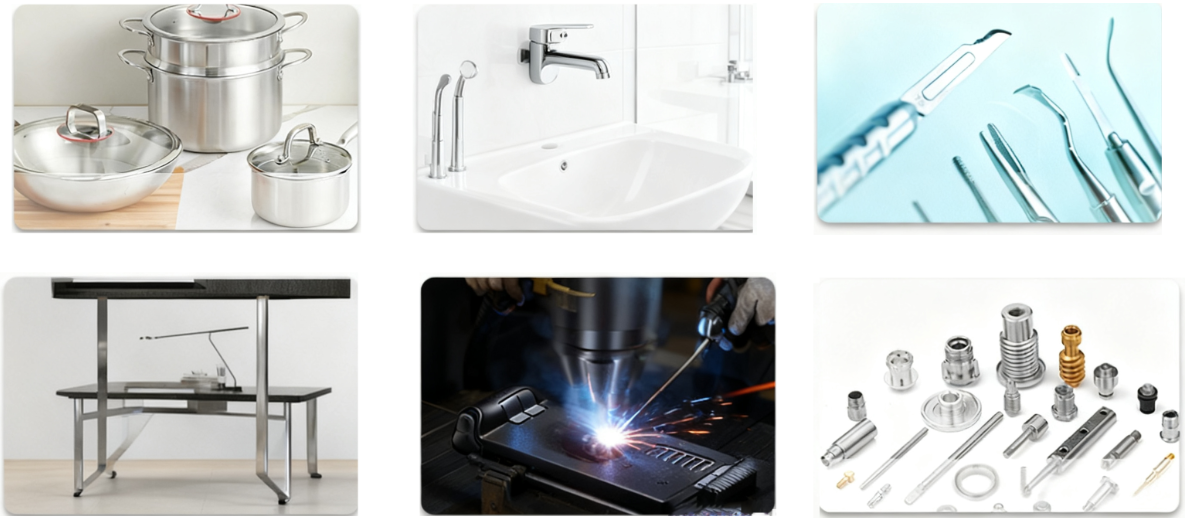

The FH-808 Nickel Barrel Plating Brightener is widely applied in:

Electronics Industry – Connectors, terminals, and micro-components requiring uniform brightness.

Hardware Manufacturing – Screws, fasteners, and decorative parts with strong Corrosion Resistance.

Automotive Industry – Precision metal components with nickel underlayers for durability.

Aerospace & Aviation – Small mechanical parts requiring uniform protective plating.

Consumer Goods – Household hardware and accessories with bright nickel finishes.

General Industrial Plating – Any mass-produced items where barrel nickel plating is preferred.

Q1: What is FH-808 mainly used for?

A1: FH-808 is specially formulated for nickel barrel plating, ensuring bright, uniform deposits on small parts and bulk hardware.

Q2: How does FH-808 perform compared to conventional nickel brighteners?

A2: FH-808 offers higher throwing power, longer bath stability, and better uniformity, especially in large-scale production.

Q3: Is FH-808 suitable for both ferrous and non-ferrous substrates?

A3: Yes, it can be used on a wide variety of substrates, including steel, copper, and zinc alloys.

Q4: Does FH-808 require frequent bath maintenance?

A4: No, FH-808 is designed for easy maintenance and long bath life, reducing operating costs.

Q5: Can FH-808 be used as a base layer before chrome or gold plating?

A5: Yes, FH-808 nickel deposits provide an excellent undercoat for further plating processes.

Q6: What industries benefit most from FH-808?

A6: Electronics, hardware, automotive, aerospace, and general manufacturing all rely on FH-808 for reliable nickel barrel plating.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.